Our Machinery

– Detailed Specifications

Our Advanced Equipment

CNC Wire-Cut EDM-Electronica Sprint cut

CNC Wire-cut EDM-Mitsubishi Make

VMC(COSMOS)-1050mm x650mm x610mm

VMC(COSMOS)-650mm x450mm x500mm

ZNC EDM(JOEMARS)- 650mm x400mm x200mm

Conventional Machineries

Laser Marking Machine

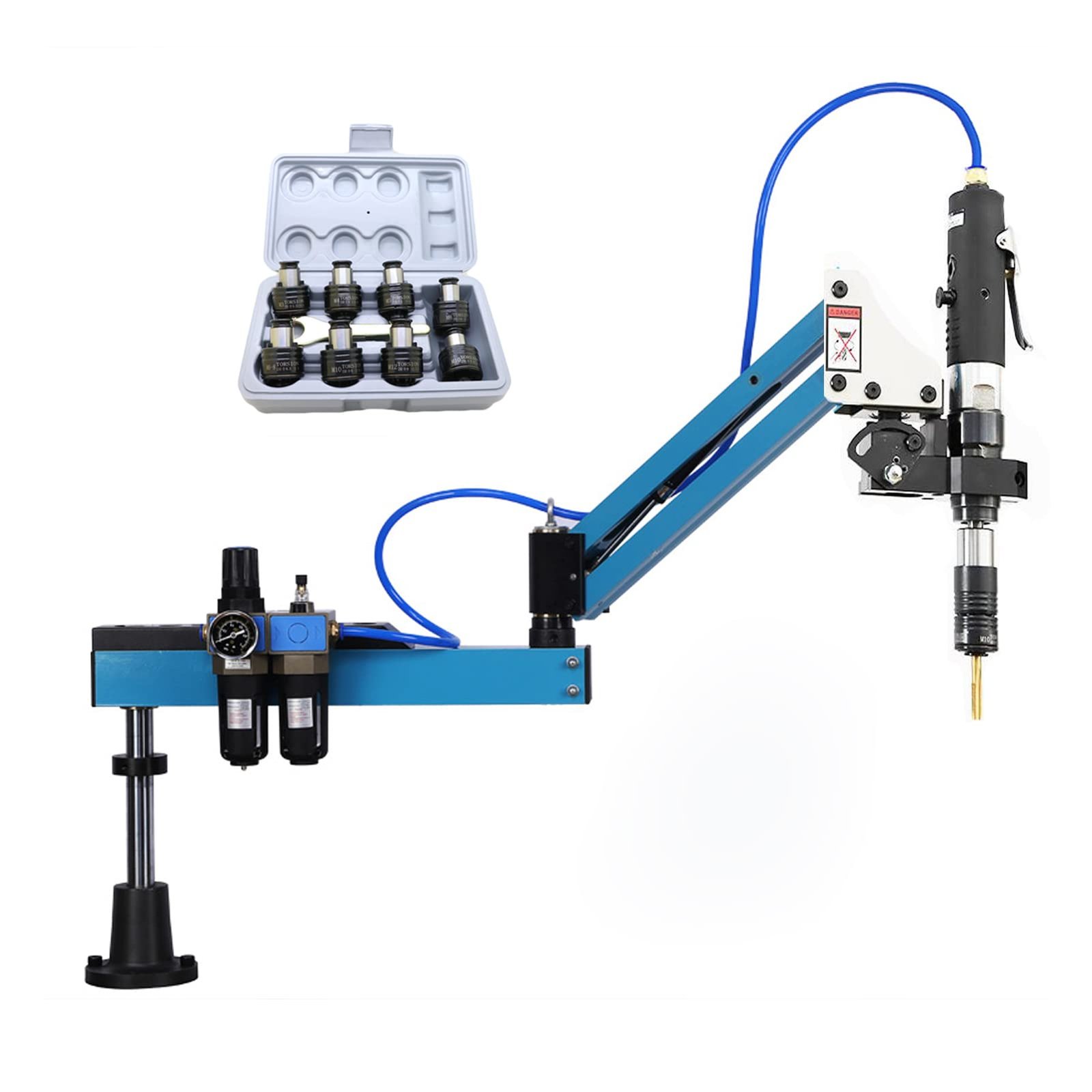

TAPPING MACHINE

CNC Lathe

Milling Machines

Surface Gtinder Machine

CNC Bending

1. CNC Wire Cut Machines

High-Precision Cutting

Our CNC Wire EDM Machines ensure ultra-fine cutting accuracy, ideal for intricate tool and die applications.

🛠 Machines in Use:

✅ Mitsubishi MV1200S (400×300×220 mm) – 1 Unit

✅ Electronica Sprintcut (400×300×200 mm) – 1 Unit

🔹 Benefits: High-speed cutting, minimal material waste, and exceptional finish for precision tooling.

2. VMC (Vertical Machining Centers)

Advanced Milling & Drilling

Our VMC machines allow for precision milling, drilling, and finishing of complex components with unmatched speed.

🛠 Machines in Use:

✅ COSMOS VCM1060 (1050×650×600 mm) – 2 Units

✅ COSMOS VCM640 (650×450×500 mm) – 1 Unit

🔹 Benefits: Multi-axis machining, increased productivity, and superior surface finishing.

3. EDM (Electrical Discharge Machines)

Intricate Tooling Capabilities

EDM technology helps us create complex moulds and die components with precision.

4. CNC Laser Cutting & Bending

High-Speed Metal Processing

Our CNC Laser Cutting and CNC Bending Machines provide high-accuracy cutting and forming solutions for sheet metal components.

5. Conventional Machining

Versatile Manufacturing Support

We also employ a variety of conventional machines to support diverse machining operations.

6. Special Purpose Machines (SPMs)

Custom Solutions for Precision Engineering

We design and manufacture Special Purpose Machines (SPMs) for high-precision applications in the automotive and industrial sectors.

Why Our Machinery Stands Out?

High-Precision, High-Speed Production

Meeting industry standards.

Automation & Efficiency

Faster turnaround and cost savings.

Custom-Built Solutions (SPMs)

Tailored to unique production needs.

Global Standards Compliance

Serving top automotive & industrial brands.

Scalable & Future-Ready

Continuous upgrades for better performance.

High-speed metal processing

clean edges, precision bending.

Address List

About Us

Contact us

- +91 7767986000

- +91 9899292025

- info@kartiktools.com

- Plot No. 4, B-Block, Gali No. 1, Duhai Industrial Area, Ghaziabad, Uttar Pradesh 201206